We custom-design each cold room for every project. We offer panels with widths of 1180 and 1100 for container transport, with a maximum panel length of 12 m and a broad range of thicknesses to meet the most stringent insulation requirements.

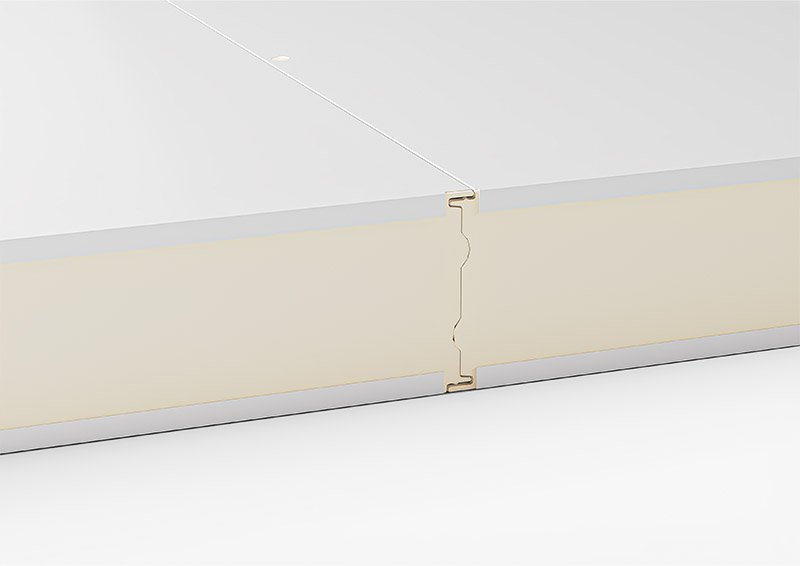

Panel joint systemWe employ an eccentric hook system to ensure optimal tightness at the joints. Additionally, we provide the option of manufacturing without joining mechanisms.

Panel ready for assemblyFeaturing thermal bridge breaks and sword-shaped supports for the roof.

Our manufacturing system allows us to adapt much more easily to the demands of our customers, both in terms of delivery times and in terms of sizes, thicknesses and other specific requirements.

Instant responseEnabling instantaneous replacement of any panel in the event of damage during installation. In the event of damage during installation.

Easy assemblyThe eccentric hook system and the factory preparation of the panels facilitate the assembly and ensure the quality of the assembly.

KIDE has developed a double tongue and groove system which, together with the hook system, gives the panel the best performance in terms of watertightness and fire resistance.

The hook fastening system ensures the adjustment of one panel against the other, achieving maximum airtightness without depending on the installer. The stainless steel hook prevents the system from rusting and ensures its removability.

In recognition of this, the advantages of our hook fastening system are also the advantages of our hook fastening system mean that it is quicker and easier to and ease of assembly compared to conventional systems.